Immobilized Biocatlyst Panels coming soon to a laboratory near you!

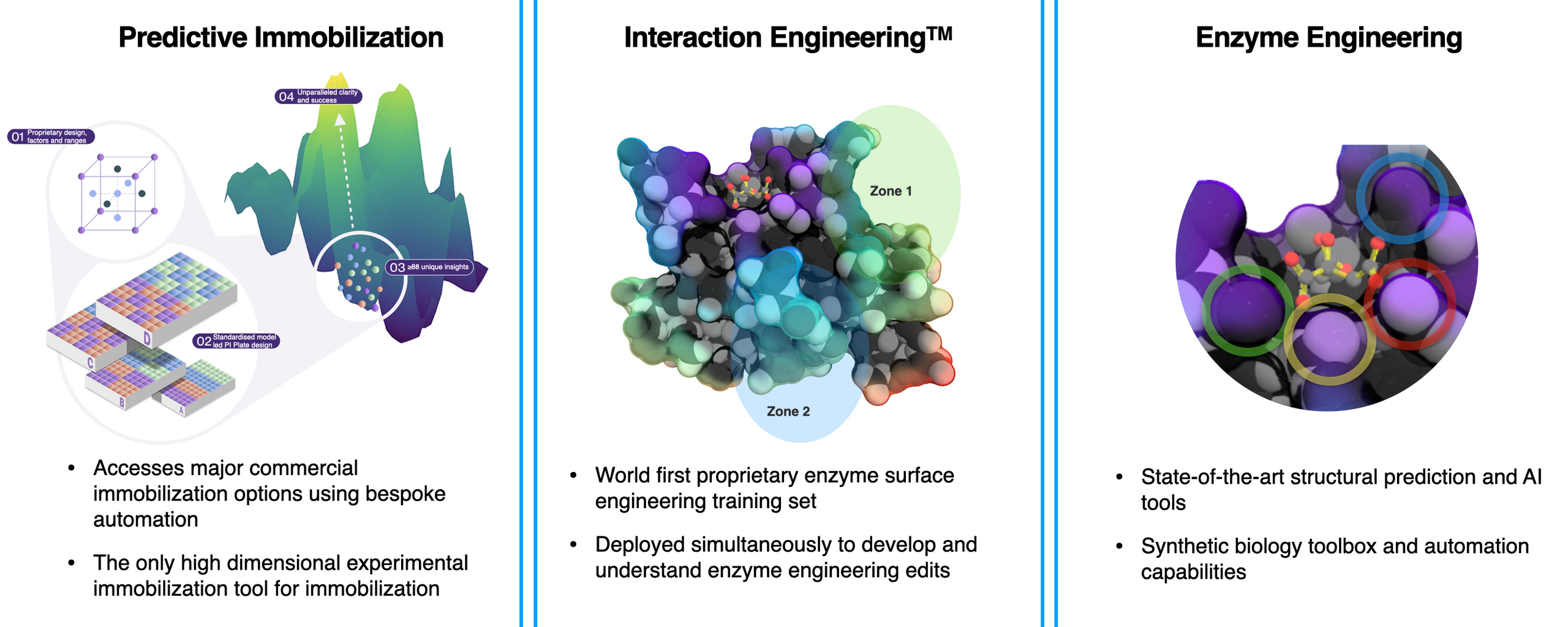

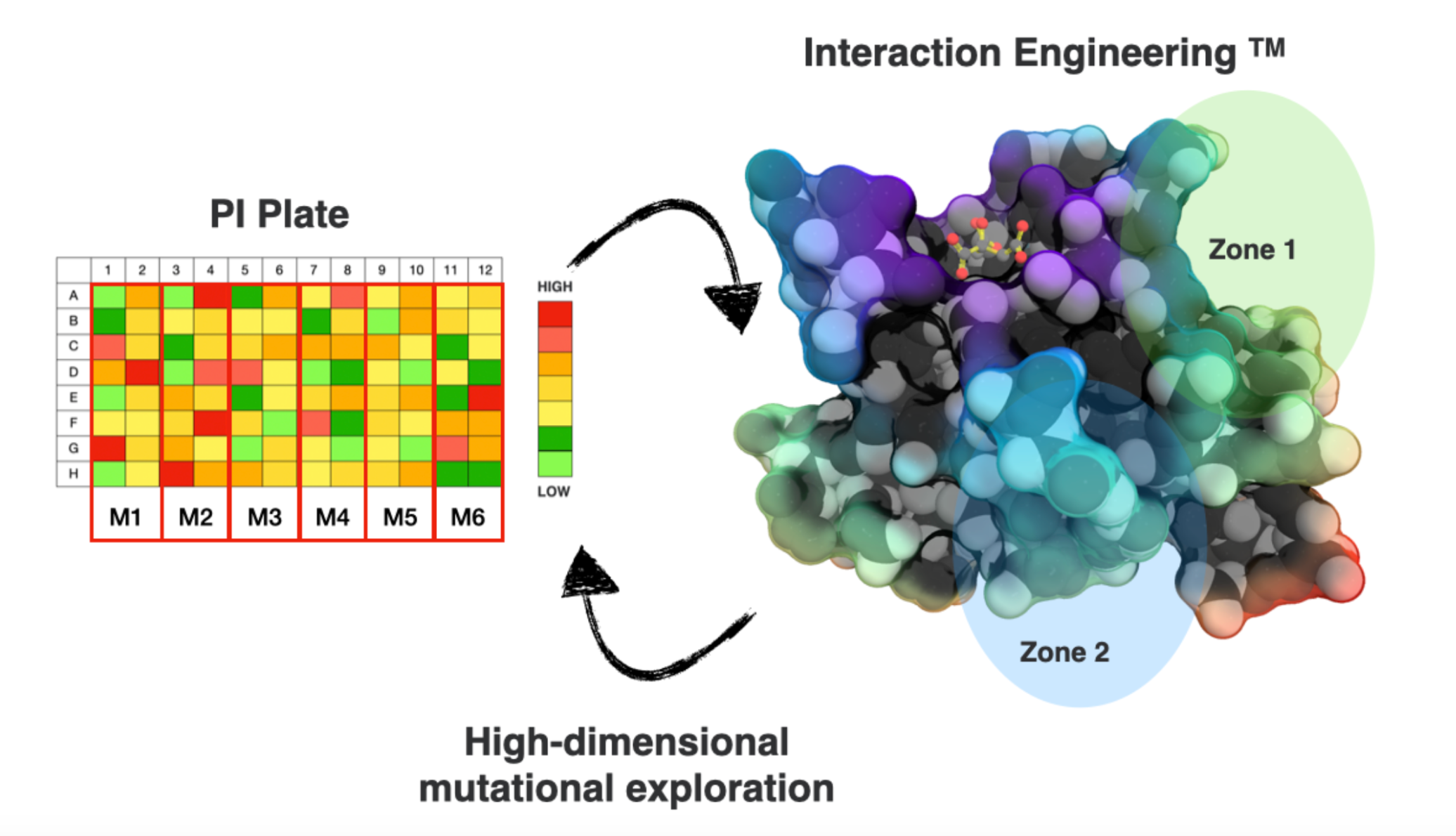

The team at FabricNano are preparing to launch a range of off-the-shelf immobilized enzymes. They will serve the biocatalysis needs of the pharmaceutical, fine chemicals and cosmetics industries. These Immobilized Biocatalysts are a product of our Immobilization EngineeringTM platform and were identified using our Predictive Immobilize Plate technology.

These Immobilized Biocatalysts will:

- Accelerate development timelines and cost savings: drop-in off-the-shelf enzymes can save months to years of development time and save hundreds of thousands in development costs.

- Enable access to biocatalyst supply at scale: no need to worry about the assembly or scale of supply, we ensure QC’d immobilized enzymes arrive for both stirred tank and flow reactor processes.

- Deliver clear next-steps: where >10X performance is still required, we’re here to help you succeed using FabricNano’s proprietary Immobilization EngineeringTM platform.

Our first set of Immobilized Biocatalyst Panels will include:

- Immobilized Ketone Reductases

- Immobilized Ene Reductases

- Immobilized Baeyer–Villiger Monooxygenases

- Immobilized Lipases

Sounds interesting? Reach out to VP R&D Vishal Sanchania for co-development opportunities via email: vishal@fabricnano.com.

Schedule introductory call: Vishal Sanchania (VP R&D)